-

Products

View -

Select Your Vehicle

Change - Go

- No Favorites

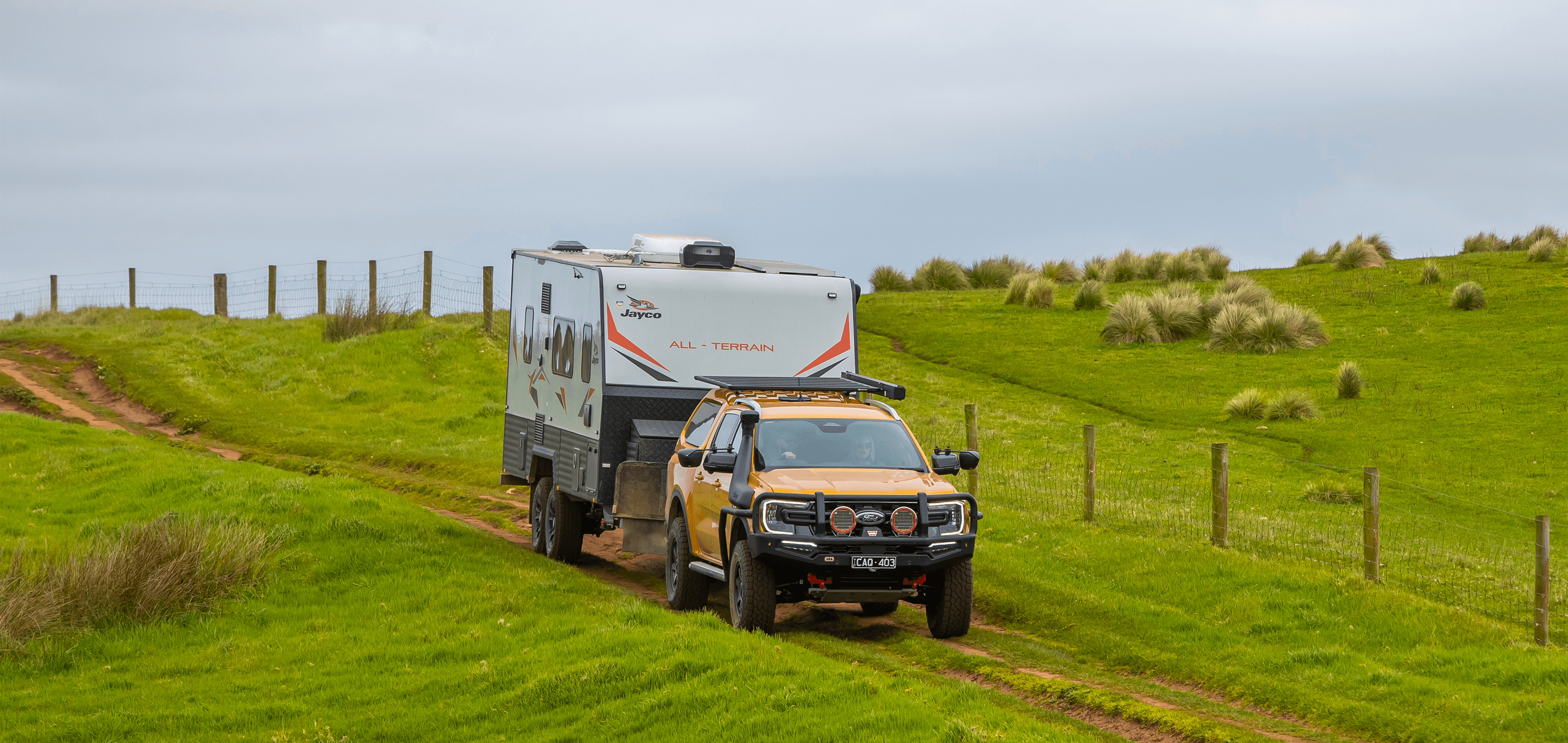

PROTECT YOUR RIG WITH OUR QUALITY ARB BULL BARS NZ-WIDE

Vital for remote area travel, ARB Bull Bars will provide substantially improved protection for vulnerable mechanical components, whilst providing a solid base for mounting other accessories like driving lights, winches and CB antennas. ARB Bull Bars are air bag-compatible, which means their installation will not affect your vehicle’s crush rate and airbag triggering.

ARB bars are all superbly designed, engineered and manufactured in-house by us. This attention to detail not only maintains maximum functionality (especially relevant with the inclusion of modern safety sensors and technology), but also ensures they complement the look of your vehicle.

ARB manufactures a number of different bars from the sleek Summit and Sahara styles, to the more functional Commercial Bar, as well as lightweight options like our StealthBar and SpartanBar.

You can find our quality ARB bull bars NZ-wide through your nearest store or stockist. For tried and tested bull bars you can rely on, visit ARB NZ today. We’ll make sure your rig is ready for any on-road and off road conditions conditions.

Bull Bar Engineering

Engineering a bull bar requires careful consideration of a number of factors to ensure it properly serves its purpose. Factors such as vehicle design, crush rate, air bag deployment, approach angles, accessory fitment, strength, weight and aesthetics are incorporated into every ARB bar before it enters production.

You simply won’t find a more thoroughly designed and manufactured vehicle protection system than an ARB bull bar.

Air Bag Compatibility

ARB has invested heavily in vehicle crash barrier tests to validate the performance and compliance of its air bag-compatible bull bars. To ensure compatibility, ARB assesses each vehicle’s frontal crush characteristics and replicates the crush rate in the design of each air bag-compatible bull bar and mounting system.

Using this method ensures that the vehicle’s crush rate and air bag triggering are not altered when a bull bar is installed.

Aesthetics and Finish

Each ARB bull bar is specifically designed to complement the unique contours of individual vehicle models. This ensures the best possible fit, look and functionality for a particular vehicle.

All ARB bars are finished in a durable powder coat, and you can colour-code them to match your vehicle, further enhancing the bar’s appeal and providing a more integrated look.

Side Rails & Side Steps

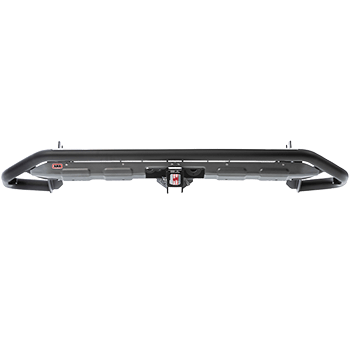

SUMMIT REAR STEP TOW BAR

SUMMIT RAW REAR STEP TOW BAR

REAR BUMPERS & TIRE CARRIERS

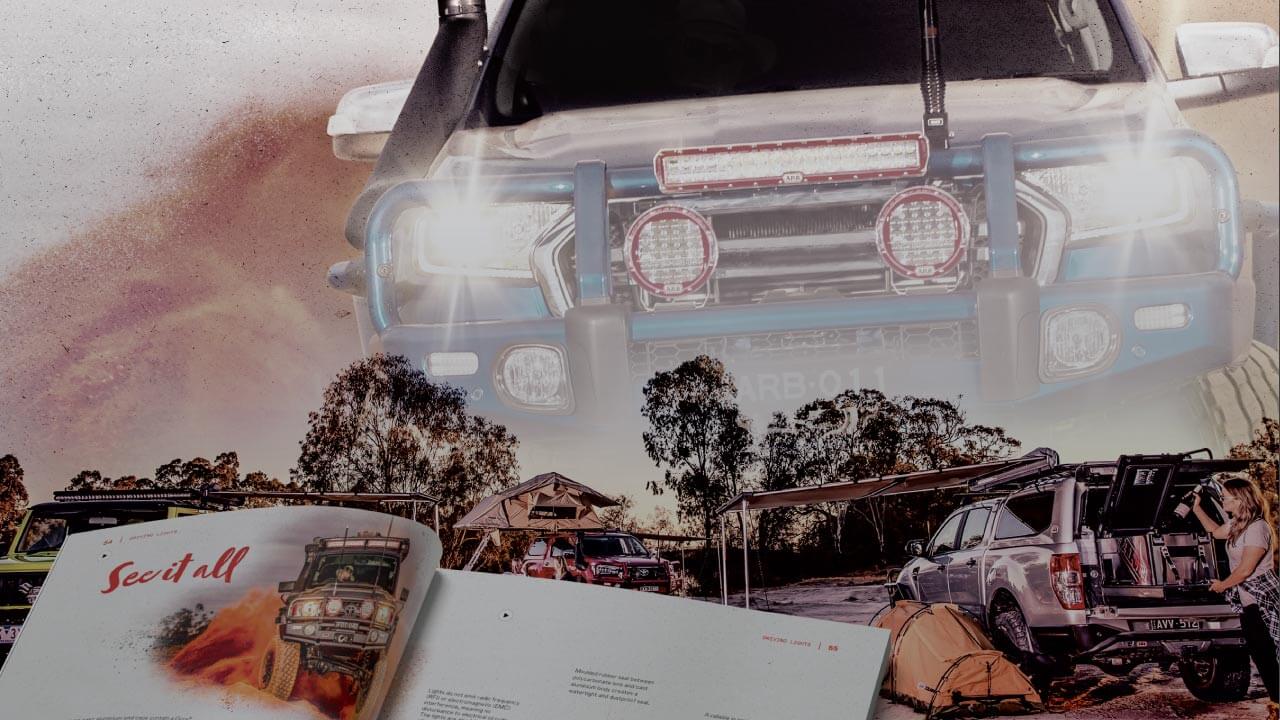

ARB BULL BAR MANUFACTURING

Follow an ARB bull bar through the entire manufacturing process. From a flat sheet of steel, experience every stage of our state-of-the-art factory in Melbourne, Australia, and take a unique look at the effort, passion and attention to detail required to build the world’s best 4×4 bull bars and protection equipment.

Shot entirely on a GoPro, this video provides the ultimate in behind-the-scenes action.

Uncover the gear as well as some tips and tricks you will need for your next adventure off grid! Read here!

View online or order a printed copy

It’s that simple, subscribe and you’re in the draw. Plus, you’ll receive ARB’s regular 4x4 CULTURE magazine, exclusive promotions, and the latest product news delivered straight to your inbox.

*Terms and conditions apply